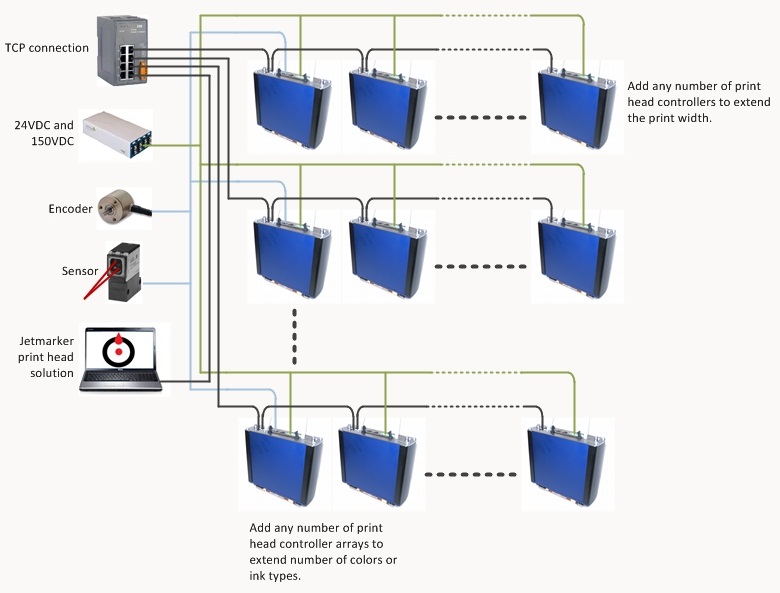

- Build array sizes from one to any number of heads

- Add any number of arrays from one to any number of arrays (colors)

- Vertical print resolution from 50 dpi to 200 dpi

- Horizontal print resolution from 1 dpi to 1200 dpi

- Print speed exeeding 40KHz, equaling approx. 10 meters per second at 200 dpi

- Easy to use programming interface

- Readout of status information, print head temperatures

- Setting of print head temperatures

- Upload images directly to the arrays or into a print queue

- Override temperature, nurse and dropwatch settings

- Server solution for setup, control and monitoring the system

- Configuration of the system

- Logging and reporting of status and error conditions

- Control of external ink tank temperatures

- Use any FUJIFILM Dimatix print head

- Individual adjustable fire curves include rise time, pulse with, fall time and amplitude

- Nurse pulse settings for keeping the printing fluid alive during stops between prints

A PHC system is a flexible one. The basic parts are:

- Computer for running the JetMarker Print Head Solution (JPHS)

- Product sensor to trigger the printout

- Encoder/tachometer for controlling the print speed

- Power supplies

- Standard TCP switch

Hereafter it is up to the specific requirements of your system. Each PHC is an autonomous printing device having no knowledge of any other PHC’s in its vicinity. The print width can be expanded to any width needed also the number of colors/inks is variable to any degree. The JetMarker Print Head Solution will take care of distributing the correct configuration and data to each PHC.

With any PHC a software application for configuration and controlling the system is delivered. It is called the JetMarker Print Head Solution and besides configuration it provides basic printing facilities. It runs as a server enabling third-party clients to connect to the PHC server from any location.

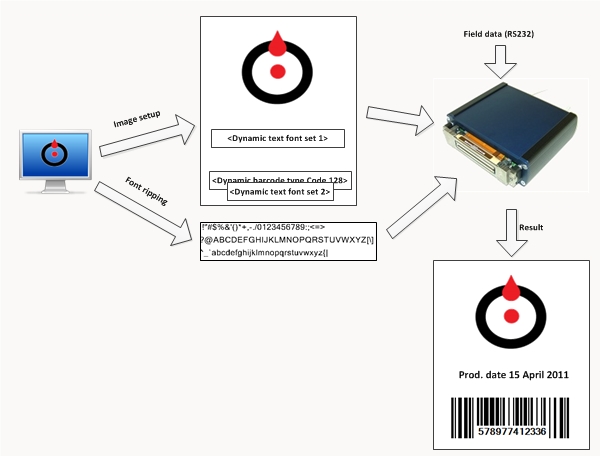

The PHC also supports dynamic fields that can be changed between each printout either via the JetMarker Print Head Solution or a direct RS422 connection to a PHC using the RS232 protocol. Each PHC supports up to four dynamic fields that can be either a barcode or a text. These fields are then joined with a static background image residing in the PHC.

|

|

|

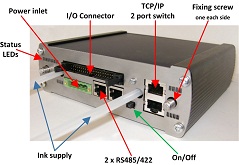

| Front connectors | System with 6 PHC width and 4 colors | PHC side view |